Enter any two known values and press calculate to solve for the others.

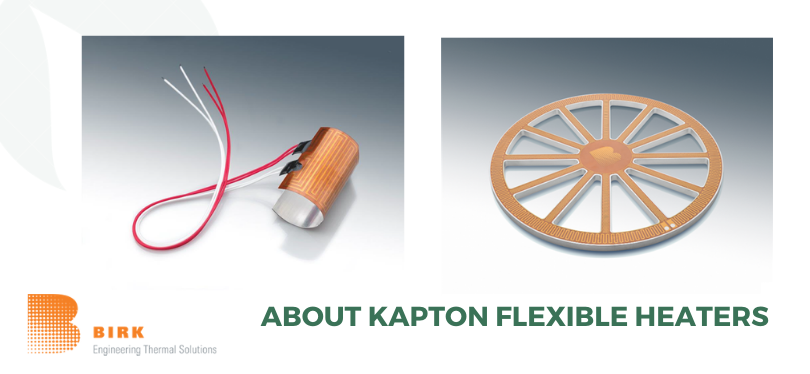

Heating is an important process in both stagnant and dynamic applications. In fact, controlled and uniform heating is an integral process for many critical applications that require specific temperature ranges to ensure crucial analysis or delivery. This is where flexible heaters are used. Most of these are polyimide film heaters, which are also known throughout the industry as Kapton® heaters. Polyimide flexible heaters are low-profile, thin heating elements that Birk Manufacturing can customize with shaded watt densities or multiple zones so that customers receive the most optimal heating solution. While the heater’s low profile and flexibility are primary lures for those seeking a Kapton® heater, Birk’s ability to fully tailor its heaters and then adhere to or laminate to a multitude of shapes and sizes provides additional inducements for those seeking a heating solution. Kapton® heaters are excellent heating solutions that provide fast thermal cycling so that products can both heat up and cool down quickly. This post discusses the details of Kapton® heaters, their applications, and benefits.

Kapton® flexible heaters offer accurate heating and can be bonded directly to heat sinks, thermal wells, chucks, and much more. This permanent bonding ensures fast and accurate heat transfer. The heaters can be integrated with assemblies such as fuses, sensors, probes, and other electronic devices to offer a full turnkey solution. Kapton®, originally developed by DuPont, is used in various types of the Kapton heaters that have varying temperature capacities and bonding systems. These include FEP Teflon adhesive, acrylic adhesive, and all-polyimide film heaters. FEP-bonded Kapton® and all-polyimide Kapton® have a temperature capability of 260°C (500°F), and acrylic-bonded Kapton® has a temperature capability of 120°C (250°F). Below are some benefits of choosing a Kapton® heater.

Kapton’s flexible design, uniform heating, and customizability are used in mission-critical or no-fail applications. Some of the industries where the critical application of Kapton® heaters are needed are noted below.

Are you looking for a reliable heating solution for your application? If so, ensure you purchase a Kapton foil heater from a reliable Kapton heater manufacturer and supplier. Birk Manufacturing is a reliable manufacturer and provider of thermal solutions that include Kapton polyimide film heaters.