Enter any two known values and press calculate to solve for the others.

Temperature monitoring and control is a critical requirement in the medical industry. To accomplish this, the industry uses various diagnostic and analytical equipment integrated with temperature control systems, such as flexible heating elements and sensors. There are different types of flexible heating elements used in medical applications. Of these, polyimide heaters and silicon rubber heaters are the most popular. These flexible heaters are chosen due to the distinct properties that make them compatible with medical industry applications. Owing to their increasing importance today, it is easy to find several manufacturers of these systems on the market. However, Birk Manufacturing, Inc. stands tall among them due to their ability to deliver these systems in custom specifications and with superior quality. This post guides you through different aspects of these flexible heating elements and their role in different applications.

Thermal analysis is an essential part of human health analysis and diagnosis. Body temperature plays an important role in human health; therefore, it is essential to monitor and control it effectively. Several medical analysis techniques, like blood analysis, tests for hypothermia and hyperthermia, and so on, are highly dependent on thermal analysis. Along with thermal analysis, many treatments, such as surgical procedures, intravenous therapy (IV), oncology, and incubation, are highly affected by the thermal conditions in the surroundings. These requirements are met through the use of thermal systems.

Considering the high significance of temperature monitoring and control, Birk Manufacturing Inc. acknowledges the stringent thermal standards in the medical industry. To meet specific needs, the company offers the following thermal systems for the medical industry. These systems are compliant with high-quality standards, such as ISO9001, ISO13485, AS9100, and ITAR regulations.

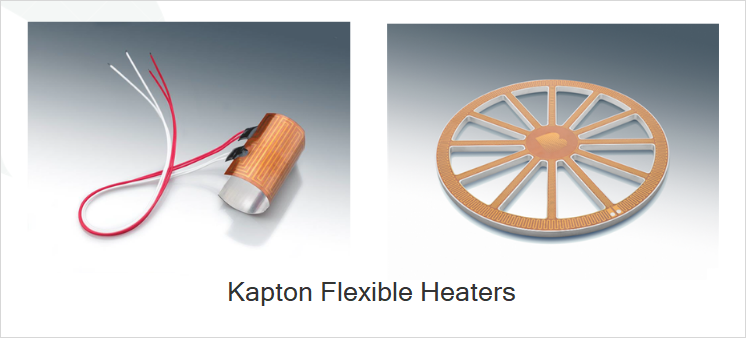

Due to the following properties of Kapton® heating solutions, these products can be integrated into medical diagnostic and analytical equipment.

Due to the following properties of silicone rubber heating solutions, these heaters are suitable for use in insertion heater assemblies in medical equipment.

![]()

The company can manufacture both of the above-mentioned thermal systems for multi-zone/dual-zone designs and in custom watt densities to meet typical application requirements.

The thermal solutions offered by Birk Manufacturing are of great significance in the following medical-industrial applications.

Along with the Kapton and silicone rubber heaters, Birk Manufacturing, Inc. offers high-quality temperature sensors that are fit for medical diagnostic and analysis equipment.